Expandable and Mobile Command Center

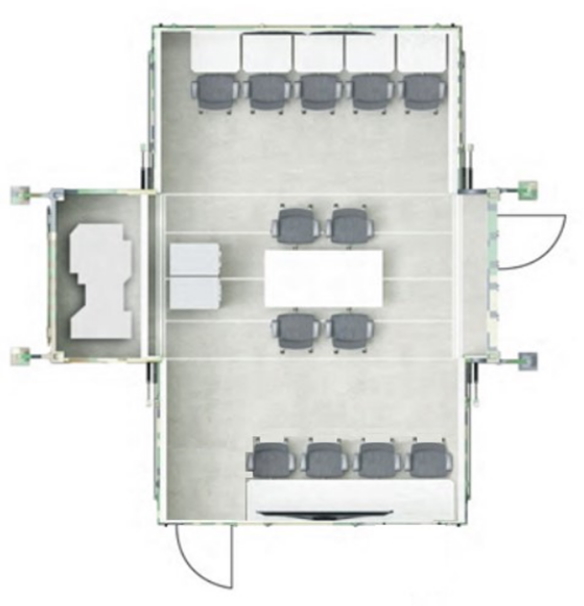

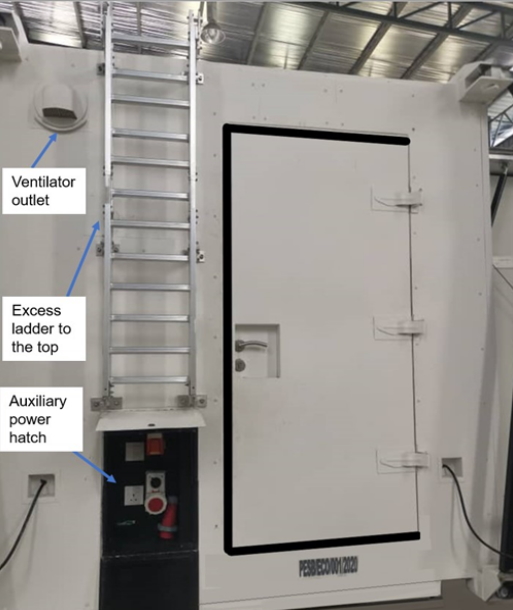

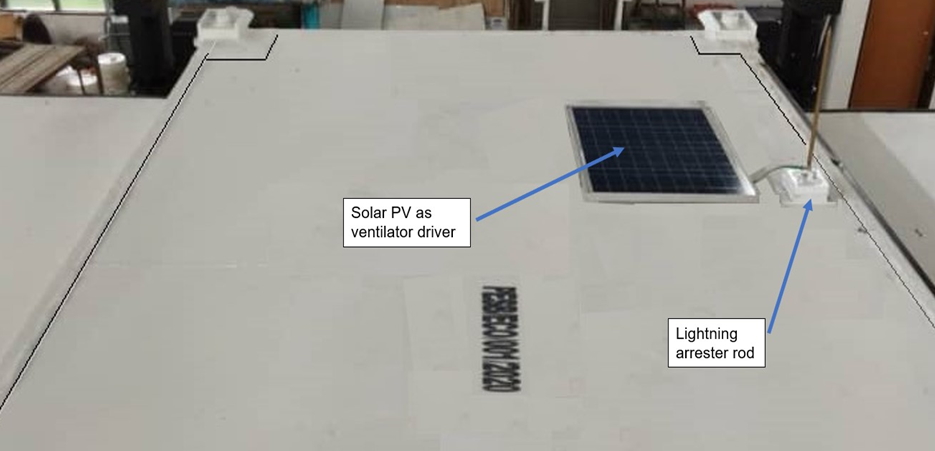

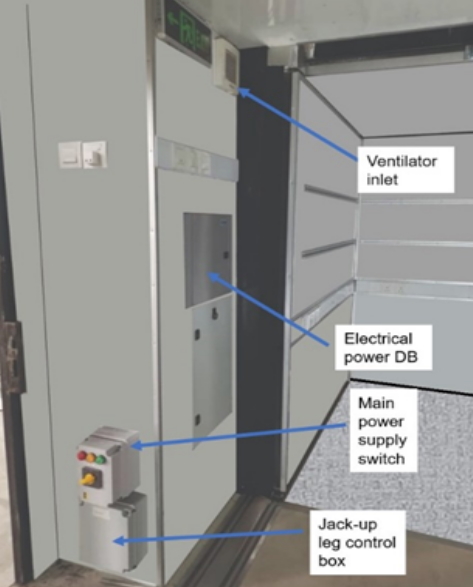

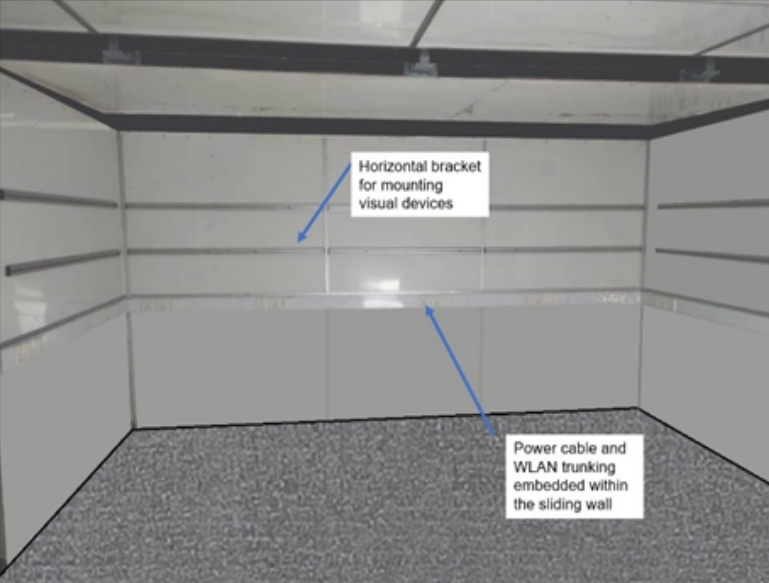

An expandable and mobile command center is a shipping container-based workspace for stationing personnel. It is equipped with proper facilities to undertake the task it which it is designed to. In general, they are used for control and surveillance, in military and civilian settings. It has the capability to expand in a “1-to-3” mode to provide adequate working space and equipped with power generation, AC and self-lifting facility for easy land mobility purpose.