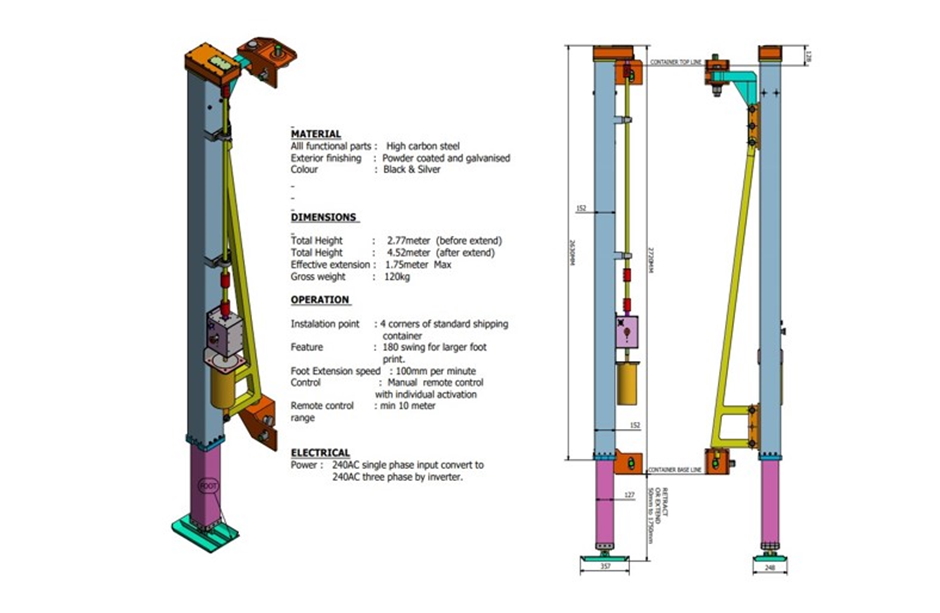

The system will be incorporated onto the container by attaching for independent units called ‘jack-up’ legs. The jack-up units consist of four vertical supports with flexible plates, mounted at the end corners. Each of them has a lifting capacity of half of the container total carrying capacity. This assures of high level of safety when in use. The self-lifting system is set up modularly for greater ease of use meaning each of the jack-up leg can be operated manually in conjunction with inclination device. Alternately the legs can be programme to be simultaneously lowered or raised if the ground surfaced is relatively flat.

The system will be incorporated onto the container by attaching for independent units called ‘jack-up’ legs. The jack-up units consist of four vertical supports with flexible plates, mounted at the end corners. Each of them has a lifting capacity of half of the container total carrying capacity. This assures of high level of safety when in use. The self-lifting system is set up modularly for greater ease of use meaning each of the jack-up leg can be operated manually in conjunction with inclination device. Alternately the legs can be programme to be simultaneously lowered or raised if the ground surfaced is relatively flat.

It is currently designed to carry loads of up to 15 T and is capable for lifting heights of up to 1700 mm. The legs are attached to containers at the ISO corners together in conjunction with tough brackets. The product comes with high corrosion protection treatment suitable for tough and tropical operations. The company is capable to design similar systems for heavier load requirements where the product is very much built to customer’s request.

Apart from corrosion, the jack-up leg unit also features dust and sand-proof telescopic square tubes with an internal encapsulated spindle driven by an electric motor. The system is suitably used on containers, vehicles and functional units that have to be aligned and stabilised relative to the ground surface.